Acronym: HaloFreeEtch

Title: Novel approaches for halogen-free and sustainable etching of silicon and glass

| Call | HORIZON-EIC-2023-PATHFINDERCHALLENGES-01-04 |

| EU nr | 101161153 |

| Period | 48 months - 01.09.2024 to 31.08.2028 |

| Project budget | € 3,997,735 |

| VUB budget | € 672,500 |

| Contact | Wim De Malsche (Group leader µFlow group and Academic Director MICROLAB core facility) Filip Legein (Business Development Manager µFlow Cell and operational manager MICROLAB) |

What is HaloFreeEtch, and why is it important?

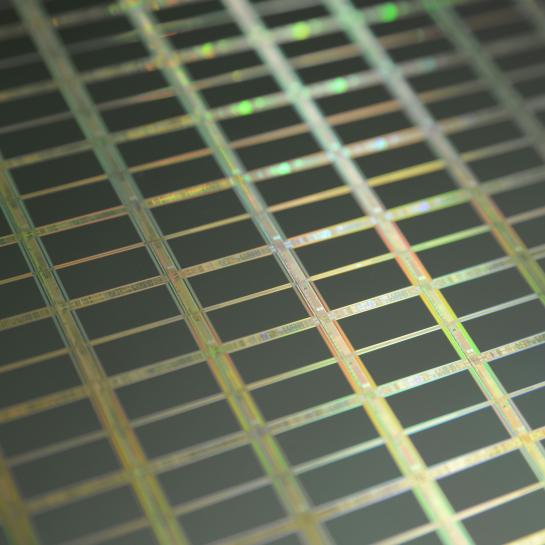

HaloFreeEtch is a groundbreaking research project aimed at transforming a critical step in the manufacturing of electronics, namely plasma etching, into a more sustainable process. Traditionally, plasma etching heavily relies on halogens, particularly fluorochemicals, which are harmful to both the environment and human health. Our goal is to develop new etching processes that are completely free of these harmful chemicals, reducing the environmental footprint of semiconductor manufacturing.

Can you tell us more about the context that led to this project?

The need for sustainable plasma etching has grown alongside increasing EU regulations aimed at phasing out fluorochemicals, including recent moves by countries like The Netherlands, Germany, and Sweden to completely ban PFAS. Additionally, with the European Chips Act launched by the European Commission, there's a significant urge to bring semiconductor manufacturing back to Europe, making it more crucial than ever to find environmentally friendly solutions.

What makes HaloFreeEtch different from past efforts to reduce the environmental impact of plasma etching?

Unlike past efforts, which have mostly focused on incremental changes, like optimizing processes to use fewer or less harmful chemicals, HaloFreeEtch takes a much broader and more fundamental approach. We’re combining advanced multi-scale modelling, a model-based life cycle analysis, and innovative technological routes to create new, halogen-free etching processes. Our aim is not just to reduce the use of harmful chemicals but to eliminate them, making the process more sustainable and economically viable.

How will HaloFreeEtch achieve these goals?

We’re using a novel combination of lab-scale research and computational techniques to identify and validate new etching chemistries that are both effective and environmentally friendly. This includes a comprehensive sustainability and life cycle analysis to ensure that the processes we develop are not only cleaner but also efficient and cost-effective. The project aims to systematically tackle these, with a strong interdisciplinary team working together over the next four years. Academic expertise from Belgium (VUB), Germany (TUC and FRAUNHOFER ENAS) and Austria (GRAZ UG) will be combined with expertise from the industry from PlasmaSolve, WH Tinexta Group and LioniX.

What impact do you expect HaloFreeEtch to have on the industry?

HaloFreeEtch has the potential to revolutionize the semiconductor industry by setting a new standard for sustainability in manufacturing. Furthermore, the processes we develop could serve as a blueprint for other industries that rely on plasma etching, strengthening the EU’s long-term position in the global chips market and helping to make electronics manufacturing more environmentally responsible on a global scale.