While lasers are now essential in numerous industrial fields from telecommunication to sensing, many applications require the simultaneous or sequential use of different wavelengths. This imposed the use of either many different lasers or so-called “tunable” lasers. The former requires optical switches, robust micrometer precision of several optical elements, simultaneous control and monitoring of several lasers, thus leading to bulky and complex systems. On the other hand, tunable lasers only emit a single wavelength at once, tuning is slow (several microseconds or longer) and can require complex commands.

| Multiple separated lasers | Tunable lasers | Multi-wavelength lasers with control system |

Simultaneous emission | Yes | No | Yes |

Wavelength tuning | Fast (require ext. switches) | Slow | Fast |

Single chip (monolithic integration) | No | Yes | Yes |

Control mechanism | Simple / Several control parameters | Complex | Simple / one parameter |

Footprint | Large | Small | Small |

Power consumption | High | Low | Low |

Applications | Optical Communication (DWDM) | Optical Communication (DWDM typ. spare device), |

|

Solution

Multi-wavelength lasers – devices having the capability to emit at different wavelengths selectively – have been proposed but the lack of an efficient and precise control mechanism made them unsuitable. The VUB Brussels Photonics Team B-PHOT, in collaboration with the Institute for Applied Physics of the Technical University Darmstadt, has developed a wavelength control system for multi-wavelength lasers to combine the best of both worlds. The all-optical control loop is monolithically integrated with the laser and gives precise control over the multi-wavelength emission through a single control voltage parameter. It allows for precisely balancing the different emission wavelength – e.g. to reliably obtain equal output power at different wavelengths – or quickly switch between wavelengths at the nanosecond timescale. The control system is compatible with generic platforms and mass manufacturable.

Competitive advantages

- Single control parameter

- High wavelength suppression ratio (> 30-50 dB)

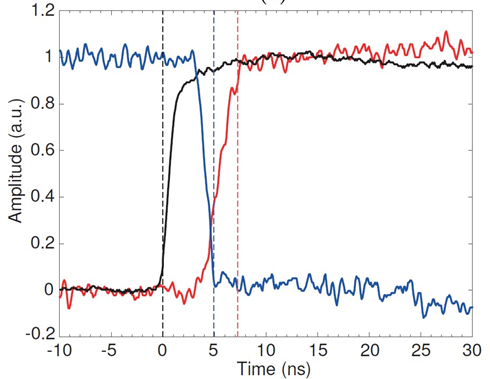

- Fast switching capability (nanosecond range)

- Monolithic integration with the laser

- Small footprint: 0.7 mm² on Indium Phosphide

- Low power consumption ( 1 mW)

- Compatible with generic foundry platforms

Current drawbacks

- Control system designed for a specific laser/set of wavelengths

- Finely tailored design required for wide wavelength separation

- Risk of dynamical instabilities when aiming for ultrafast control or very high suppression ratio

Ongoing developments

- Improvements of the control efficiency for a wide range of laser configurations (including current and temperature settings)

- Optimization of the system against wavelength separation mismatch to reduce customization needs.

- Improvement of the dynamical stability

Collaboration details / Looking for

- Setting up joint R&D collaborations with industrial partners for upscaling of the control system and for targeting specific industrial use cases.

- Entering into license agreements or partnerships to implement the design into industrial products.

B-PHOT Brussels Photonics

Prof. Martin Virte

[E] martin.virte@vub.be

Switching between the two wavelengths of a dual-wavelength laser (blue and red) using our control system. In black is the control parameter.